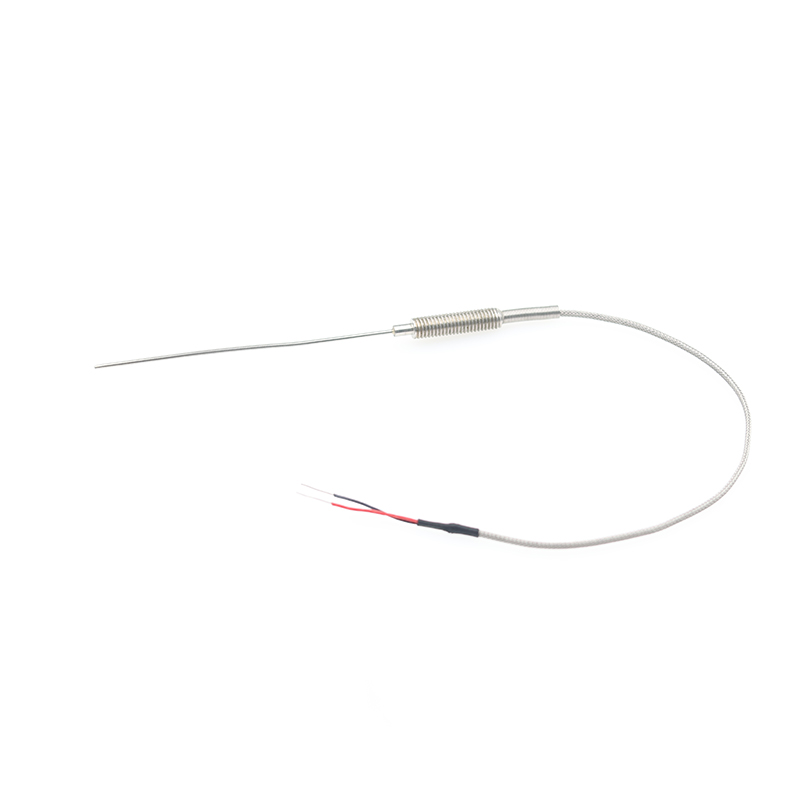

Product Model: SK-WRKK1-ab2(M8x32)C/IK1x300 -Φ1.5x100 Thermocouple type K type Thermocouple dia...

Thermocouple Temperature Sensors Manufacturers

Thermocouples measure temperature by the electric potential generated by two different metals.

When two different metal conductors (or semiconductors) are connected into a closed circuit, the thermoelectric potential (voltage) will be generated in the circuit if the two contacts are at different temperatures. This phenomenon is called the Seebeck effect. The value of the thermoelectric potential is proportional to the temperature difference between the two ends, and the temperature can be calculated by measuring the voltage.

| Type | K-Type, N-Type, E-Type, J-Type, T-Type, S-Type, R-Type, B-Type, etc. |

| Temperature Range | -200°C to 1800°C |

| Accuracy | I, II |

| Response Time | 0.1–30 Seconds |

| Probe Diameter | 0.2 mm–30 mm |

| Probe Length | 5 mm–200 m |

| Probe Material | Stainless Steel 304, 304L, 316, 316L, 321, 321L, 310s, Inconel 600, NiCr, etc. |

| Connection Type | Simple Type, Junction Box, Plug-in Type |

| Measuring End Type | The Exposed Type, The Bottom Collision Type, The Insulation Type, The Separated Insulation Type |

| Insulation Material | MgO, Al₂O₃, Fiberglass, PTFE, Ceramic, etc. |

| Sheathed Material | Stainless Steel, Inconel, Ceramic, etc. |

-

-

K-type armored thermocouple

K-type armored thermocoupleProduct item No.: SKT-2575 Thermocouple type K type Cable length 2200 ± 20mm Thermocouple di...

-

K-type armored thermocouple for oven use (core probe, multi-point temperature sensor )

K-type armored thermocouple for oven use (core probe, multi-point temperature sensor )Product item No.: SKT-2553 Thermocouple type K type Thermocouple q'ty 2 Accuracy 50~100 ℃ : ±...

-

K-type thermocouple for oven use - humidity

K-type thermocouple for oven use - humidityProduct item No.: SKT-2555 Accuracy 0~300 ℃ : ±1K Measuring Range 0~300 ℃

-

K-type armored thermocouple for oven use (thermocouple for cabinet)

K-type armored thermocouple for oven use (thermocouple for cabinet)Product item No.: SKT-2556 Thermocouple type K type Accuracy 0~300 ℃ : ±1K Working end form I...

-

K-type thermocouple for oven use (thermocouple for steam generator)

K-type thermocouple for oven use (thermocouple for steam generator)Product item No.: SKT-2557 Thermocouple type K type Accuracy 0~300 ℃ : ±1K Working end form I...

-

K-type armored thermocouple for oven use (thermocouple for quenching)

K-type armored thermocouple for oven use (thermocouple for quenching)Product item No.: SKT-2558 Thermocouple type K type Accuracy 0~300 ℃ : ±1K Working end form I...

-

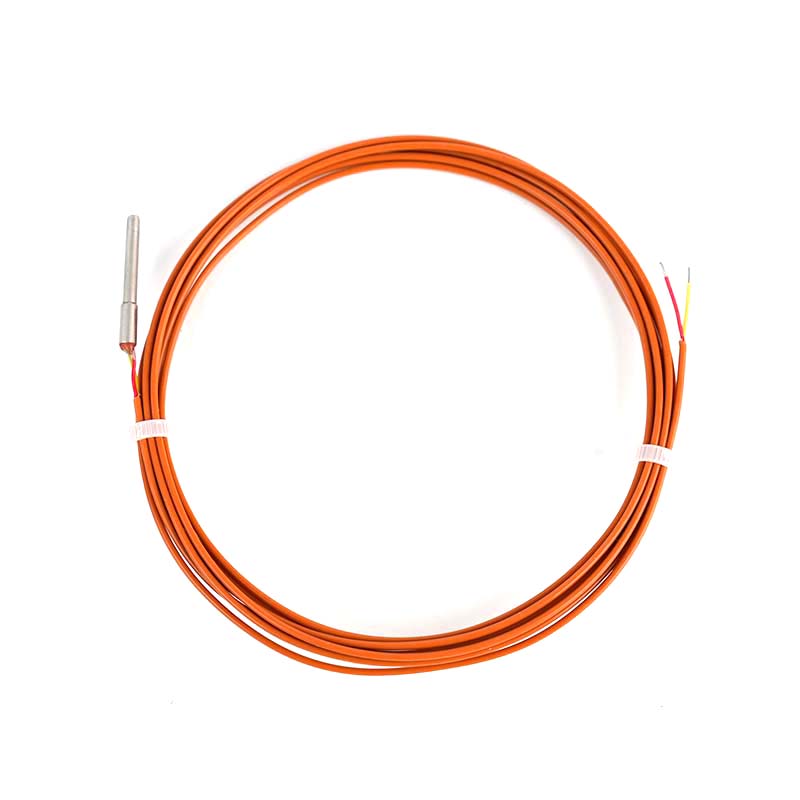

K-type thermocouple

K-type thermocoupleProduct Model: SKT-2579 Thermocouple Type K-type Accuracy ±1.5℃ Measuring Range 0~700℃ Co...

-

K-type thermocouple sensor

K-type thermocouple sensorProduct item No.: SKT-2592 Thermocouple type K type Structure Sheathed Accuracy Class 1 Pro...

-

K type variable cross-section armored thermocouple

K type variable cross-section armored thermocoupleProduct item No.: SKT-2593 Thermocouple type K type Structure Variable cross-section sheathed ...

-

N type armored thermocouple

N type armored thermocoupleProduct item No.: SKT-2633N Thermocouple type N type Structure Sheathed Accuracy Class 1 Te...

-

K-type aviation thermocouple

K-type aviation thermocoupleProduct Model: SK-WRK-ab/IK1x300 -Φ3x15 Thermocouple type K type Cable length 300 ± 5mm Ther...

Sook High Tech (Jiangsu) Co., Ltd. was established in 2015, with a registered capital of 30.5 million yuan. Has won High-tech enterprise, National science and technology small and medium-sized enterprise, Software enterprise, Member of China Machinery Industry Standardization Technology Association, Council Members of Sensor and IoT Industry Association, Council Members of China Instrument Industry Association Sensor Branch and Council Members of Jiangsu Import and Export Chamber of Commerce.

As a professional China OEM Thermocouple Temperature Sensors Manufacturers and ODM K-type Thermocouple Temperature Sensors Factory

, SOOK High Tech focuses on the design, production, sales and integration of various sensors for smart cars and industrial fields, as well as cables and heaters for the industrial field.

Has an annual production capacity of 600,000 sensors of various types. There are more than 2,000 items of exhaust temperature sensors, 450 items of NOx sensors, and 1,300 items of ABS sensor, which are exported to Europe and the United States.

Learn about our industry exhibition information and recent events in our company.

-

What Is a NOx Sensor and Why Is It So Important in Modern Vehicles?

If you work with modern diesel vehicles—or you're responsible for engines, aftertreatment systems, or emission compliance—you’ve probably heard customers ask: "What exactly is a NO...23 -

What is an NTC EGT Sensor?

In the fields of automotive and industrial measurement, the NTC EGT sensor is another widely utilized tool for monitoring exhaust gas temperatures. 1. Definition and Core Principle...16 -

Why are PTC sensors more accurate than ordinary sensors?

In automotive emission monitoring and high-temperature industrial operations, the precision of an Exhaust Gas Temperature (EGT) sensor directly impacts engine efficiency and safety...09 -

What is the specific role of the PTC EGT Sensor in DPF regeneration?

The Specific Role of the PTC EGT Sensor in DPF Regeneration: 1. Real-time Temperature Monitoring The sensor is installed upstream of the DPF and collects exhaust gas temperature in...02

What are the typical industrial applications of K-type thermocouple temperature sensors?

1. Gas Turbine and Engine Exhaust Temperature Monitoring

Due to their wide temperature measurement range (-200°C to 1250°C) and excellent oxidation resistance, K-type thermocouple temperature sensors are commonly used for real-time exhaust temperature monitoring in gas turbines, aircraft engines, and automotive engines, helping to optimize combustion efficiency and provide fault warnings.

2. Metallurgy and Metal Heat Treatment

In the heat treatment of metals such as steel and aluminum alloys, precise monitoring of the furnace temperature profile is essential. K-type thermocouples maintain stable output in high-temperature environments, making them the preferred sensor for critical locations such as furnaces, heat treatment furnaces, and forging dies.

3. Petrochemical and Chemical Process Control

Petroleum refining and chemical reactors often involve high-temperature, corrosive media. The high-temperature and corrosion-resistant properties of K-type thermocouples enable reliable temperature measurement of critical nodes such as reactors, heat exchangers, and steam pipes, ensuring production safety.

4. Industrial Furnaces and Ceramic Firing

High-temperature firing processes for ceramics, glass, and other materials require extremely high temperature uniformity. K-type thermocouples can be placed at multiple locations within the furnace to achieve multi-point temperature measurement, helping to achieve uniform temperature control and improve product quality.

How to determine if a thermocouple is damaged or malfunctioning?

1. Check the relationship between the output voltage and the reference temperature

Use a calibration furnace or thermostat at a known temperature to perform on-site calibration of the thermocouple. If the measured voltage deviates from the reference table value by more than the specified tolerance (e.g., ±1%), the thermocouple may be deteriorating or the contacts may be corroded.

2. Visually inspect the wiring and protective tube

Inspect the thermocouple wires for cracks, oxidation, or insulation damage. Cracks or leaks in the protective tube (e.g., stainless steel or ceramic) can easily allow ingress of foreign media, causing signal drift.

3. Perform a continuity test using a multimeter

Use a multimeter to measure the resistance or continuity across the thermocouple while it is cold. If an open circuit or extremely low resistance is detected, it indicates a break or short in the wire.

4. Monitor long-term drift trends

Record the thermocouple's historical output curve using a data acquisition system. If a gradual increase or decrease in deviation occurs under the same operating conditions, the thermoelectric potential of the thermocouple has degraded and needs to be replaced.

English

English Español

Español Français

Français

简体中文

简体中文