Product Model: SKKPLS-4*0.22mm Structure Coated high-toughness copper conductor 7 x 0.20mm Pol...

Stainless Steel Signal Cables Manufacturers

The stainless steel signal cable is composed of solid coated high-toughness copper conductor, polyimide insulation layer, polyimide filling layer, and 316L stainless steel tube. The entire sheathed complex forms a multi-layer protective structure to ensure zero interference in signal transmission under harsh conditions such as temperature, strong corrosion, and high vibration. The product has high strength and flexibility. The armored outer sheath is passivated to form a chromium-rich oxide film, which significantly improves the rust resistance and eliminates frequent maintenance. This product can be custom-made, the core wire can be double-core wires, four-core wires, six-core wires, or eight-core wires. The products are mainly used in oil wells, deep sea, navigation, the chemical industry, and other fields.

| Conductor Material | Coated high-toughness copper conductor |

| Conductor Size | 0.2mm×7 |

| Insulation Material | Polyimide |

| SUS316 Tube Thickness | 0.4mm |

| Cable Diameter | 4.0±0.05mm |

| Cable Temperature Resistance | -50℃ to +380℃ |

| Cable Breaking Force | 9kN |

| Minimum Bending Radius | 200mm |

| Withstand Voltage | 300VDC |

| Insulation resistance of cable at 20 ℃: | ≥500MΩ·km |

| DC resistance of cable at 20 ℃: | ≤86Ω/km |

| Cable Capacitance | ≤0.17μF/km |

| Number of Cores | 1 pair, 2 pairs, 3 pairs, 4 pairs |

| Custom Lengths | 10mm-1000m |

| Special Applications | Oil well, Deep sea, Navigation, Chemical industry |

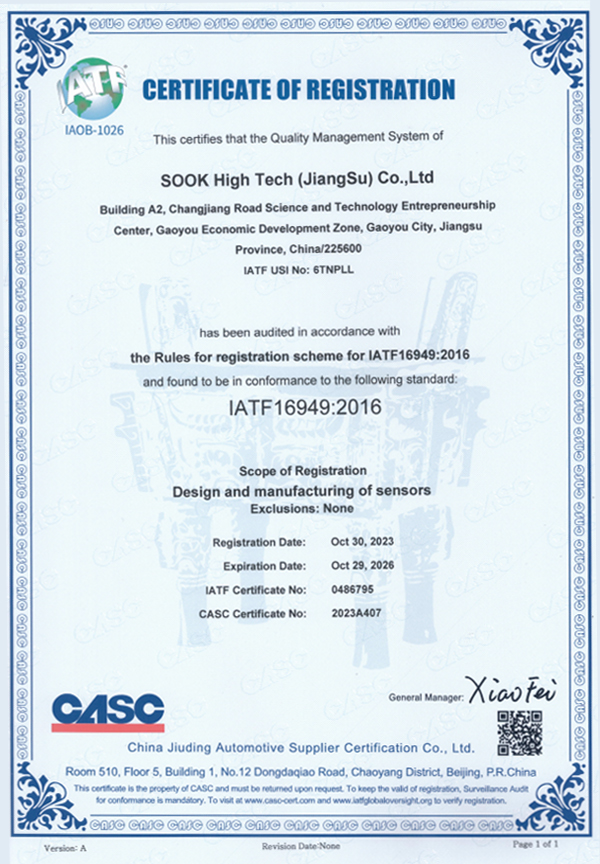

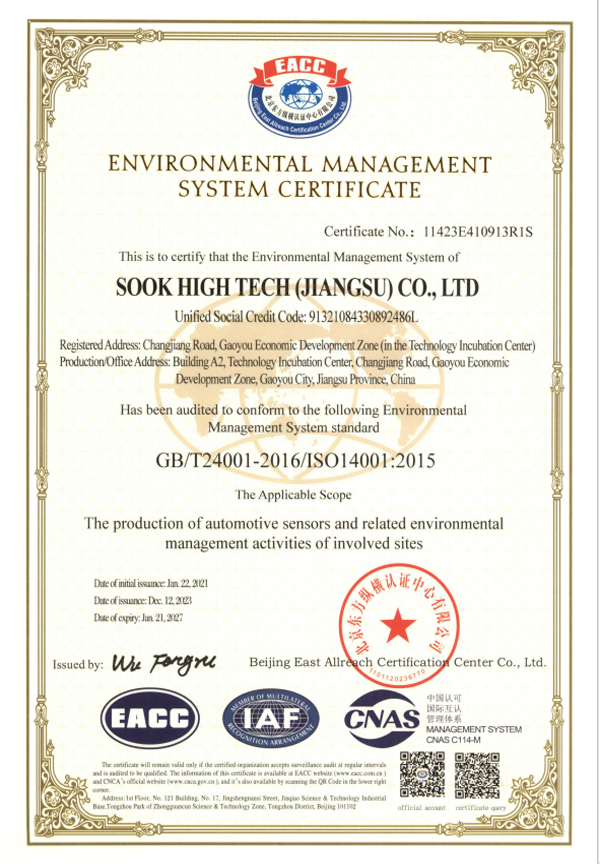

Sook High Tech (Jiangsu) Co., Ltd. was established in 2015, with a registered capital of 30.5 million yuan. Has won High-tech enterprise, National science and technology small and medium-sized enterprise, Software enterprise, Member of China Machinery Industry Standardization Technology Association, Council Members of Sensor and IoT Industry Association, Council Members of China Instrument Industry Association Sensor Branch and Council Members of Jiangsu Import and Export Chamber of Commerce.

As a professional China OEM Stainless Steel Signal Cables Manufacturers and ODM Stainless Steel Signal Cables Factory

, SOOK High Tech focuses on the design, production, sales and integration of various sensors for smart cars and industrial fields, as well as cables and heaters for the industrial field.

Has an annual production capacity of 600,000 sensors of various types. There are more than 2,000 items of exhaust temperature sensors, 450 items of NOx sensors, and 1,300 items of ABS sensor, which are exported to Europe and the United States.

Learn about our industry exhibition information and recent events in our company.

-

What Is a NOx Sensor and Why Is It So Important in Modern Vehicles?

If you work with modern diesel vehicles—or you're responsible for engines, aftertreatment systems, or emission compliance—you’ve probably heard customers ask: "What exactly is a NO...23 -

What is an NTC EGT Sensor?

In the fields of automotive and industrial measurement, the NTC EGT sensor is another widely utilized tool for monitoring exhaust gas temperatures. 1. Definition and Core Principle...16 -

Why are PTC sensors more accurate than ordinary sensors?

In automotive emission monitoring and high-temperature industrial operations, the precision of an Exhaust Gas Temperature (EGT) sensor directly impacts engine efficiency and safety...09 -

What is the specific role of the PTC EGT Sensor in DPF regeneration?

The Specific Role of the PTC EGT Sensor in DPF Regeneration: 1. Real-time Temperature Monitoring The sensor is installed upstream of the DPF and collects exhaust gas temperature in...02

What are the typical applications for stainless steel signal cables?

1. Oil wells and deep-sea drilling: In the high-pressure, high-temperature, and highly corrosive downhole environment, 316L stainless steel sheaths resist corrosion from seawater and salt spray, ensuring interference-free signal transmission.

2. Shipbuilding and marine navigation: Navigational instruments and deep-sea sonar require extremely high signal integrity. A combination of multi-layer polyimide insulation and stainless steel sheaths ensures long-term reliable operation in high-vibration and salt spray environments.

3. Chemical and petrochemical plants: Temperature, pressure, and flow sensors in production lines are often exposed to strong acids, bases, and corrosive gases. The passivation film on the outer layer of 316L stainless steel provides excellent rust resistance, reducing maintenance frequency.

4. Smart cars and industrial automation: In engine compartments or robot joints subject to high vibration and high temperatures, signal cables require both flexibility and strength. Sook High Tech's customized multi-core structures (dual-core, quad-core, hexagonal, and octal-core) precisely meet these requirements.

How should I choose a stainless steel signal cable based on transmission distance and signal frequency? 1. The higher the signal frequency, the faster it attenuates.

High-frequency signals experience greater capacitive coupling and skin effect when transmitted over long distances, leading to signal distortion. Reducing the frequency or using a larger copper conductor can effectively extend the transmission distance.

2. Voltage and Wire Diameter Combination

Increasing the drive voltage and increasing the conductor cross-sectional area (e.g., using multiple strands of thin copper wire) can reduce line impedance and improve signal integrity over long distances.

3. Maximum Cable Length Calculation

Based on the instrument loop current (typically 20mA) and the power supply voltage (24VDC), signal cable runs are generally within 100m within a load range of 500Ω–750Ω. For longer distances, shielded twisted-pair cables or repeater amplifiers can be used.

4. Multi-core Cable Selection

For systems that require simultaneous transmission of multiple signals (such as four- or eight-channel sensor arrays), multi-core stainless steel signal cables provide unified protection within a single sheath, preventing cross-interference and improving overall reliability.

English

English Español

Español Français

Français

简体中文

简体中文