Product Model: SKP2J2X1DLS-60 Shielding layers q'ty 2 Insulating layers q'ty 2 Core wire q'ty...

Inorganic Sheathed Cables Manufacturers

This product is insulated between the conductor (core wire) and the metal shielding (shell) through mineral materials (insulation layer). The number of central conductors can be single-core or multi-core. The central conductor and metal shielding layer (shell) can be austenitic stainless steel or TU2 oxygen free copper wrapped with austenitic stainless steel, Mineral materials can be aluminum oxide, magnesium oxide, or silicon dioxide; The insulation layer can be one or multiple layers (separated by a metal shielding layer), suitable for signal transmission in nuclear power plants.

Inorganic sheathed cables: durable, fire-resistant wiring for harsh environments and high-reliability applications. And can be used in nuclear spent fuel processing and other application scenarios requiring radiation resistance. It can also be used for special occasions, such as cables brought with nuclear power equipment.

| Conductor Material | Copper, 304, 304L, 316, 316L, Ni, etc. |

| Conductor Size | Φ0.5 – Φ15 |

| Insulation Material | Aluminum Oxide, Magnesium Oxide, Silicon Dioxide |

| Sheath Material | Stainless Steel, Copper |

| Voltage Range | 50V – 3000V |

| Temperature Range | -40°C – 90°C (up to 650°C for special applications) |

| Outer Diameter | 0.2mm – 20mm |

| Number of Cores | 1 core, 2 cores, 4 cores, 6 cores |

| Custom Lengths | 10mm – 1000m |

| Special Applications | High Temperature, Hazardous Areas |

| Note | Inorganic sheathed cables can be designed according to user needs. |

-

-

PEEK outer covering triple coaxial mineral armored cable

PEEK outer covering triple coaxial mineral armored cableSKP2J2X1DLS-60-PEEK Shielding layers q'ty 2 Insulating layers q'ty 2 Core wire q'ty 1 Miner...

-

Neutron type transmission armored wires for nuclear power plants

Neutron type transmission armored wires for nuclear power plantsProduct Model: SKJXDLM-18 Core wire dia. Φ0.46±0.1mm Insulation 25 ℃, IR≥ 1x1013 Ω.m Distrib...

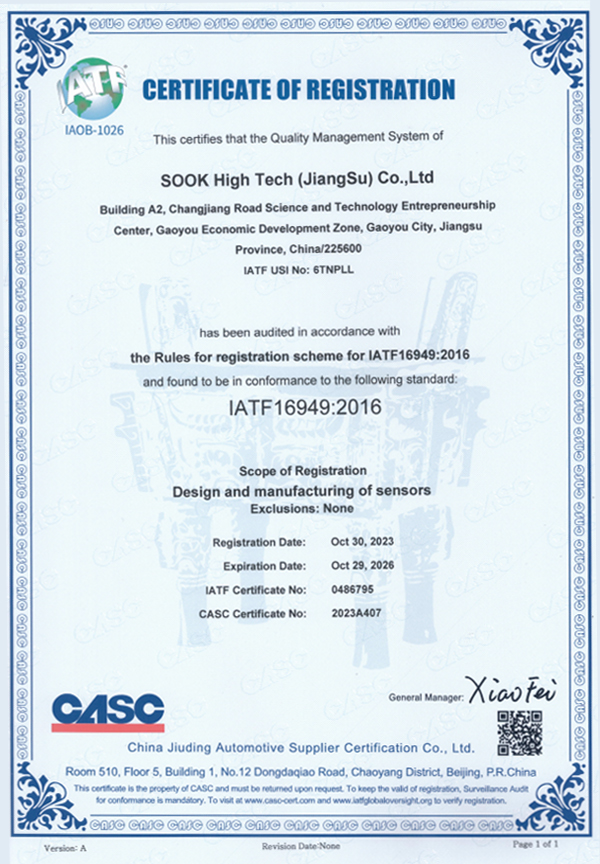

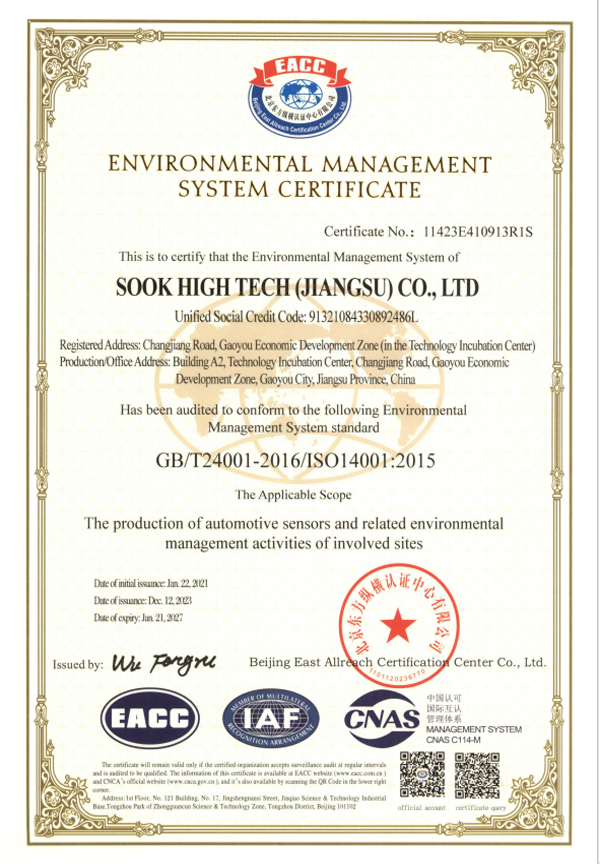

Sook High Tech (Jiangsu) Co., Ltd. was established in 2015, with a registered capital of 30.5 million yuan. Has won High-tech enterprise, National science and technology small and medium-sized enterprise, Software enterprise, Member of China Machinery Industry Standardization Technology Association, Council Members of Sensor and IoT Industry Association, Council Members of China Instrument Industry Association Sensor Branch and Council Members of Jiangsu Import and Export Chamber of Commerce.

As a professional China OEM Inorganic Sheathed Cables Manufacturers and ODM Inorganic Sheathed Cables Factory

, SOOK High Tech focuses on the design, production, sales and integration of various sensors for smart cars and industrial fields, as well as cables and heaters for the industrial field.

Has an annual production capacity of 600,000 sensors of various types. There are more than 2,000 items of exhaust temperature sensors, 450 items of NOx sensors, and 1,300 items of ABS sensor, which are exported to Europe and the United States.

Learn about our industry exhibition information and recent events in our company.

-

What Is a NOx Sensor and Why Is It So Important in Modern Vehicles?

If you work with modern diesel vehicles—or you're responsible for engines, aftertreatment systems, or emission compliance—you’ve probably heard customers ask: "What exactly is a NO...23 -

What is an NTC EGT Sensor?

In the fields of automotive and industrial measurement, the NTC EGT sensor is another widely utilized tool for monitoring exhaust gas temperatures. 1. Definition and Core Principle...16 -

Why are PTC sensors more accurate than ordinary sensors?

In automotive emission monitoring and high-temperature industrial operations, the precision of an Exhaust Gas Temperature (EGT) sensor directly impacts engine efficiency and safety...09 -

What is the specific role of the PTC EGT Sensor in DPF regeneration?

The Specific Role of the PTC EGT Sensor in DPF Regeneration: 1. Real-time Temperature Monitoring The sensor is installed upstream of the DPF and collects exhaust gas temperature in...02

What are the main structural layers of Inorganic Sheathed cables?

1. Conductor (Core)

Single-core or multi-core copper wire is used. The core material can be TU2 oxygen-free copper or copper wire coated with austenitic stainless steel, ensuring excellent conductivity and corrosion resistance.

2. Metal Shield (Sheath)

TU2 copper coated with austenitic stainless steel or stainless steel provides strong electromagnetic shielding and mechanical protection, suitable for high-radiation environments such as nuclear power plants.

3. Inorganic Sheathed cables

High-purity mineral materials such as aluminum oxide, magnesium oxide, or silicon dioxide are used. They offer high-temperature resistance, flame retardancy, and radiation resistance, making them key to cable durability.

4. Multi-layer Structure (Optional)

Multiple insulation layers can be placed between the metal shielding layers to achieve higher signal integrity and safety redundancy.

How is field splitting or splicing performed?

1. Field Cutting

Use specialized cutting tools to precisely cut the outer sheath to avoid damage to the internal metal shielding and insulation. The cut should remain smooth to facilitate subsequent splice installation. 2. Removing the Metal Shield

Manually or mechanically remove the metal shield, ensuring that the internal mineral insulation layer is not damaged. If necessary, use anti-static tools to prevent static discharge.

3. Insulation Treatment

Clean the exposed Inorganic Sheathed cables layer using a specialized cleaner to remove dust and oil, ensuring the connector end faces are clean and free of impurities.

4. Connector Installation

Use nuclear-grade metal connectors or crimp connectors. Use a high-temperature, radiation-resistant sealant or epoxy resin for secondary sealing to ensure long-term reliability in high-temperature, radiation-resistant environments.

English

English Español

Español Français

Français

简体中文

简体中文