Product Model : SK-JRB-60W-φ6 Wire length 300±10mm Heating tube dia. φ6±0.1mm Heating tube ...

Armored Heaters Manufacturers

The working principle of generating heat through the conductor using an electric current and transmitting heat to the heated body by means of radiation, convection, and conduction. The product is composed of alloy thermoelectric wire, insulating material, metal casing and three solid bodies.

It has a long service life, high mechanical strength, corrosion resistance, high thermal efficiency, uniform heating, safety and sanitation, convenient installation and maintenance, etc. In addition, it also has an outer protection pipe with a small diameter, a long length, can be arbitrarily bent into various shapes, and other characteristics.

This kind of product can directly heat solid, liquid, and gas, widely used in the petrochemical industry, mechanical electronics, aviation, aerospace, nuclear energy, household appliances and other national economies.

| Structure | Single core, Twin core |

| Power | 1W – 5000W |

| Voltage | 1V – 380V |

| Dimensions | According to the customer's requirement (Diameter, Length) |

| Core Material | Ni80Cr20, etc. |

| Temperature Range | 1°C – 1200°C |

| Sheathed Material | 304, 304L, 316, 316L, 321, 321L, 310s, Inconel 600, etc. |

-

-

Miniature heater

Miniature heaterProduct Model: SK-JRB-60W-φ10 Wire length ≥ 300mm Heating tube dia. φ10±0.5mm Heating tube ...

-

High-temperature resistant variable cross-section sheathed aerospace heater

High-temperature resistant variable cross-section sheathed aerospace heaterProduct Model: SK-KJ2-Φ2.1x1200+Φ2.4x200-400W/115V/Inconel 600 Structural feature Variable cro...

-

Flower-shaped heater

Flower-shaped heaterWire length 3000mm Heating tube dia φ4.6±0.1mm Heating tube length 3000 mm Wor...

-

High-temperature resistant variable cross-section sheathed aerospace heater

High-temperature resistant variable cross-section sheathed aerospace heaterProduct Model: SK-KJ2-Φ1.2x165+Φ2x30-2x2.5W/5V/Inconel 600 Structural feature Variable cross-sec...

-

Miniature armored electric heater

Miniature armored electric heaterProduct Model: SK-KJ-C1-12W/24V Product description Miniature armored electric heater (24V) heat...

-

Armored heater

Armored heaterProduct Model: 230V 1500W Cold terminal resistance 35.5±5%(Ω) Cold terminal insulation resista...

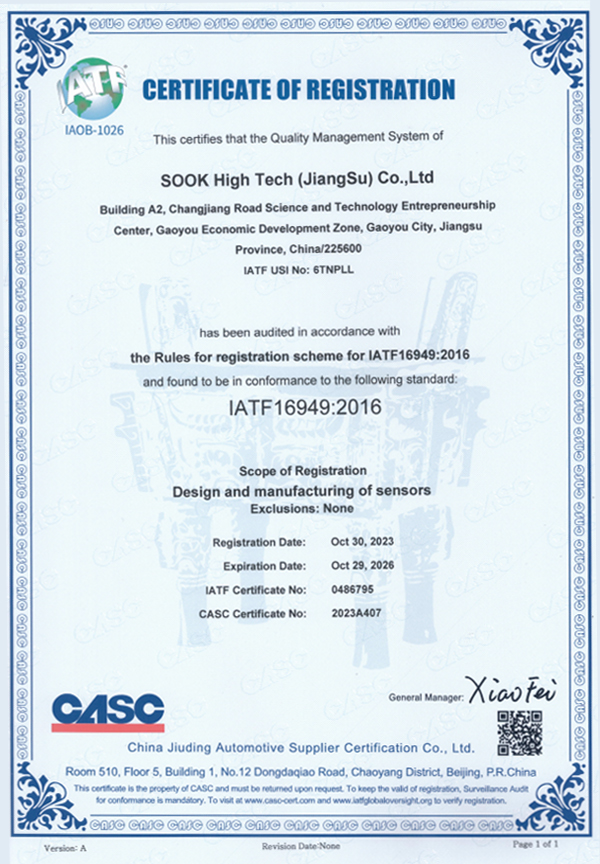

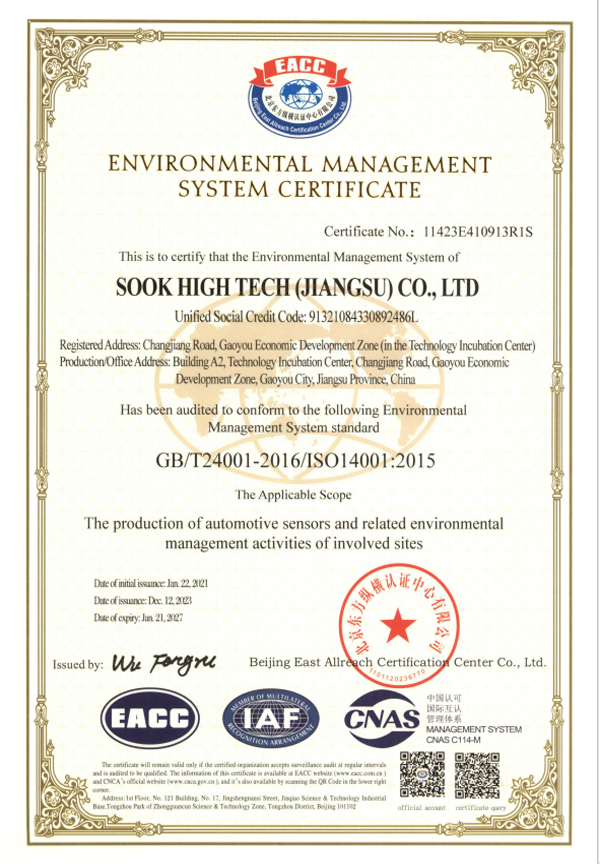

Sook High Tech (Jiangsu) Co., Ltd. was established in 2015, with a registered capital of 30.5 million yuan. Has won High-tech enterprise, National science and technology small and medium-sized enterprise, Software enterprise, Member of China Machinery Industry Standardization Technology Association, Council Members of Sensor and IoT Industry Association, Council Members of China Instrument Industry Association Sensor Branch and Council Members of Jiangsu Import and Export Chamber of Commerce.

As a professional China OEM Armored Heaters Manufacturers and ODM Armored Heaters Factory

, SOOK High Tech focuses on the design, production, sales and integration of various sensors for smart cars and industrial fields, as well as cables and heaters for the industrial field.

Has an annual production capacity of 600,000 sensors of various types. There are more than 2,000 items of exhaust temperature sensors, 450 items of NOx sensors, and 1,300 items of ABS sensor, which are exported to Europe and the United States.

Learn about our industry exhibition information and recent events in our company.

-

What Is a NOx Sensor and Why Is It So Important in Modern Vehicles?

If you work with modern diesel vehicles—or you're responsible for engines, aftertreatment systems, or emission compliance—you’ve probably heard customers ask: "What exactly is a NO...23 -

What is an NTC EGT Sensor?

In the fields of automotive and industrial measurement, the NTC EGT sensor is another widely utilized tool for monitoring exhaust gas temperatures. 1. Definition and Core Principle...16 -

Why are PTC sensors more accurate than ordinary sensors?

In automotive emission monitoring and high-temperature industrial operations, the precision of an Exhaust Gas Temperature (EGT) sensor directly impacts engine efficiency and safety...09 -

What is the specific role of the PTC EGT Sensor in DPF regeneration?

The Specific Role of the PTC EGT Sensor in DPF Regeneration: 1. Real-time Temperature Monitoring The sensor is installed upstream of the DPF and collects exhaust gas temperature in...02

What is the protective design principle behind Armored Heaters?

1. Synergistic Protection of Metal Casing and Alloy Heating Wire

A high-strength metal casing encases the alloy heating wire, creating a robust mechanical barrier to protect against shock, vibration, and external impact.

The metal casing also effectively shields electromagnetic interference, enhancing the heater's electrical safety.

2. High-Temperature Corrosion Resistance of Insulation Material

High-temperature and chemical-resistant insulation material is used internally to isolate the heating wire from the external environment, preventing short circuits and leakage.

The insulation layer also suppresses heat loss in unwanted directions, improving thermal efficiency.

3. Flexible External Protective Tubing Design

The small-diameter, long-length external protective tubing can be bent into various shapes to accommodate complex piping layouts.

This tubing not only provides secondary protection but also reduces stress concentration during installation, extending its service life.

4. Multi-Mode Heat Transfer Mechanism

Heat is transferred to the heated object through radiation, convection, and conduction, achieving uniform and rapid heating.

This combined heat transfer method improves overall thermal efficiency and meets demanding industrial heating requirements. What are the key maintenance points for armored heaters?

1. Regularly check the housing integrity

Inspect the metal housing for cracks, deformation, or signs of corrosion, and replace damaged parts promptly.

Ensure the bolts fastening the housing to the terminal blocks are secure to prevent loosening and electrical failure.

2. Inspect the insulation integrity

Use an insulation resistance meter to measure the insulation resistance to ensure it is not damp or deteriorating.

If cracks or peeling are found, replace it immediately to prevent short circuits and leakage.

3. Clean surface deposits

When operating in an environment with high levels of dust, oil, or chemicals, clean the heater surface regularly to prevent increased thermal resistance.

Use a soft, dry cloth or specialized cleaning agent; avoid using highly corrosive solvents.

4. Thermal performance verification

Monitor the actual temperature distribution of the heater using a temperature sensor or thermal imager to confirm uniform heat transfer.

If localized overheating or temperature deviations occur, check the internal heating wires for damage or poor contact.

English

English Español

Español Français

Français

简体中文

简体中文