MERCEDES-BENZC-CLASS (W203) (2000/05 - 2007/08)MERCEDES-BENZC-CLASS Coupe (CL203) (2001/03 - 2011/06...

PTC EGT Sensor Manufacturers

PTC EGT Sensor, often referred to as a PT200 or PT500 sensor, utilizes the principle that the electrical resistance of platinum changes predictably with temperature. These sensors are highly accurate and stable, making them ideal for measuring exhaust gas temperatures in automotive, industrial, and environmental applications. The sensor typically consists of a platinum wire or film encapsulated in a protective sheath, designed to withstand harsh conditions, including high temperatures and corrosive gases. By monitoring the resistance, the sensor provides precise temperature readings, which are crucial for optimizing engine performance, reducing emissions, and ensuring compliance with environmental regulations. Their reliability and durability make them a preferred choice in demanding environments.

| Sensor Type | PT200 |

| Probe Numbers | 1 |

| RTD Type | PT200 |

| Operating Temp. Range | -40 ℃ to +850 ℃ |

| Measurement Accuracy | <600℃:±4℃ |

| >600℃:±7℃ | |

| Response Time at 10m/s | <10s |

| Signal Output On the Car | Voltage |

| Design Reliability | Excellent |

-

-

A0225451926 , 0225451926 , 0051534528 PTC EGT Sensor

A0225451926 , 0225451926 , 0051534528 PTC EGT SensorMERCEDES-BENZ E320 (2007 - 2008)

-

07Z906088,SU11602 PTC EGT Sensor

07Z906088,SU11602 PTC EGT SensorVOLKSWAGEN TOUAREG (2006 - 2008)

-

07Z906088A,057906088E,057906088G PTC EGT Sensor

07Z906088A,057906088E,057906088G PTC EGT SensorAUDIQ7 (4L) (2006/03 - 2015/08)VWTOUAREG (7LA, 7L6, 7L7) (2002/10 - 2010/05)

-

03G906088AN,03G906088J,03G906088A PTC EGT Sensor

03G906088AN,03G906088J,03G906088A PTC EGT SensorAUDIA3 (8P1) (2003/05 - 2012/08)AUDIA3 Sportback (8PA) (2004/09 - 2013/03)AUDIA4 (8EC, B7) (2004/11 ...

-

55574183 , 7451955 , 0855432 PTC EGT Sensor

55574183 , 7451955 , 0855432 PTC EGT SensorOPEL ASTRA J (2009/12 - /) OPEL ASTRA J Sports Tourer (2010/10 - /) OPEL ASTRA GTC J ...

-

11787831624 , SU11263 , ES10581 PTC EGT Sensor

11787831624 , SU11263 , ES10581 PTC EGT SensorBMW M3 (2001 - 2005)BMW Z4 2008

-

03L906088G,92094048,0894044 PTC EGT Sensor

03L906088G,92094048,0894044 PTC EGT SensorVWJETTA III (1K2) (2005/08 - 2010/10) VWGOLF VI (5K1) (2008/10 - 2013/11) VWGOLF VI Varia...

-

03L906088J , 7452261 , 27320026 PTC EGT Sensor

03L906088J , 7452261 , 27320026 PTC EGT SensorAUDIA3 (8P1) (2003/05 - 2012/08) AUDIA3 Sportback (8PA) (2004/09 - 2013/03) AUDITT (8J3) ...

-

03L906088L , 7452234 ,92094077 PTC EGT Sensor

03L906088L , 7452234 ,92094077 PTC EGT SensorVWJETTA III (1K2) (2005/08 - 2010/10) VWBEETLE (5C1) (2011/04 - /) VWBEETLE Convertible (...

-

03L906088T,7452265,ASTE0025 PTC EGT Sensor

03L906088T,7452265,ASTE0025 PTC EGT Sensor2010-2014 Volkswagen Golf 2010-2014 Volkswagen Jetta

-

059906088A,92 09 4002,7452057 PTC EGT Sensor

059906088A,92 09 4002,7452057 PTC EGT SensorAUDIA4 Convertible (8H7, B6, 8HE, B7) (2002/04 - 2009/03) AUDIA8 (4E_) (2002/10 - 2010/07...

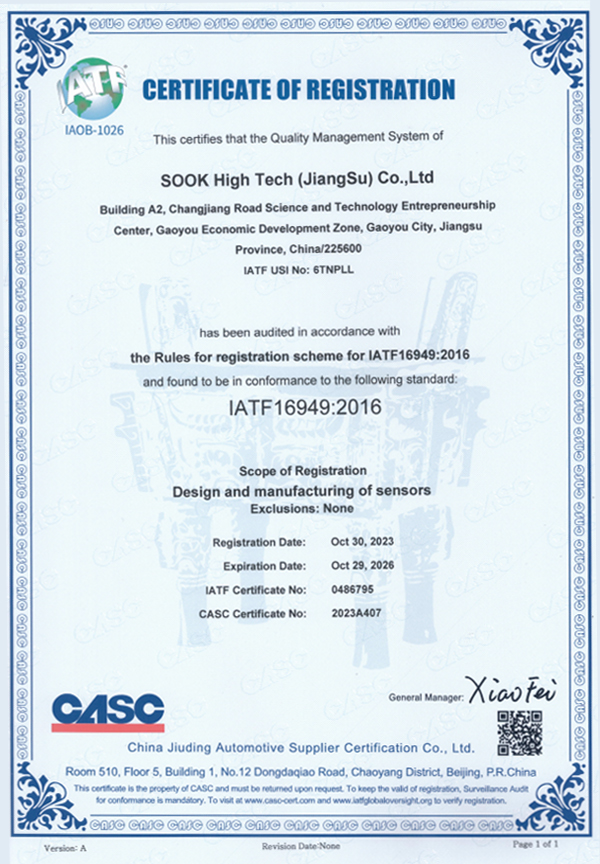

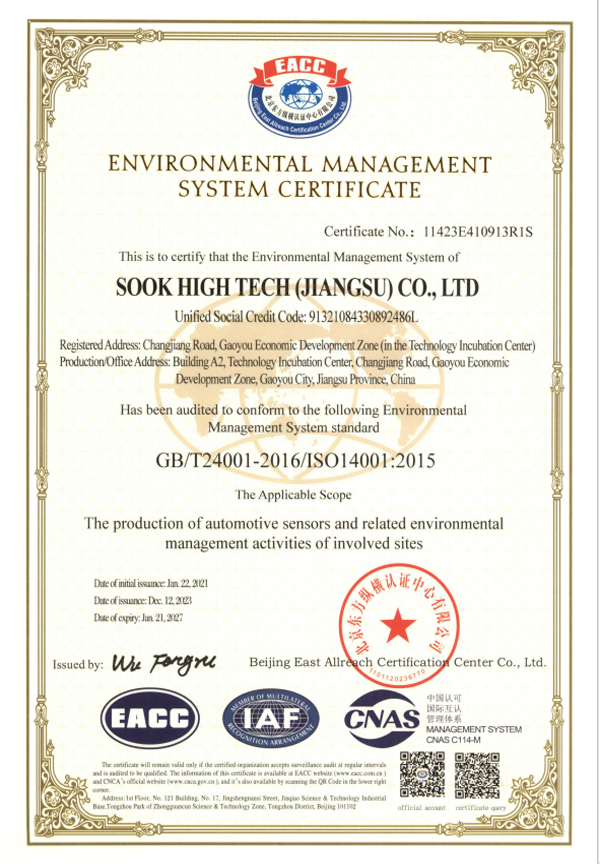

Sook High Tech (Jiangsu) Co., Ltd. was established in 2015, with a registered capital of 30.5 million yuan. Has won High-tech enterprise, National science and technology small and medium-sized enterprise, Software enterprise, Member of China Machinery Industry Standardization Technology Association, Council Members of Sensor and IoT Industry Association, Council Members of China Instrument Industry Association Sensor Branch and Council Members of Jiangsu Import and Export Chamber of Commerce.

As a professional China OEM PTC EGT Sensor Manufacturers and ODM PTC EGT Sensor Factory

, SOOK High Tech focuses on the design, production, sales and integration of various sensors for smart cars and industrial fields, as well as cables and heaters for the industrial field.

Has an annual production capacity of 600,000 sensors of various types. There are more than 2,000 items of exhaust temperature sensors, 450 items of NOx sensors, and 1,300 items of ABS sensor, which are exported to Europe and the United States.

Learn about our industry exhibition information and recent events in our company.

-

What Is a NOx Sensor and Why Is It So Important in Modern Vehicles?

If you work with modern diesel vehicles—or you're responsible for engines, aftertreatment systems, or emission compliance—you’ve probably heard customers ask: "What exactly is a NO...23 -

What is an NTC EGT Sensor?

In the fields of automotive and industrial measurement, the NTC EGT sensor is another widely utilized tool for monitoring exhaust gas temperatures. 1. Definition and Core Principle...16 -

Why are PTC sensors more accurate than ordinary sensors?

In automotive emission monitoring and high-temperature industrial operations, the precision of an Exhaust Gas Temperature (EGT) sensor directly impacts engine efficiency and safety...09 -

What is the specific role of the PTC EGT Sensor in DPF regeneration?

The Specific Role of the PTC EGT Sensor in DPF Regeneration: 1. Real-time Temperature Monitoring The sensor is installed upstream of the DPF and collects exhaust gas temperature in...02

In what systems are NTCEGT sensors commonly used?

1. Automotive Exhaust Temperature Monitoring

NTCEGT sensors are installed on the engine's exhaust manifold or exhaust pipe to measure exhaust temperature in real time, helping the engine control unit (ECU) optimize fuel injection, ignition timing, and emissions control.

2. Heating, Ventilation, and Air Conditioning (HVAC) Systems

In appliances such as air conditioners and water heaters, NTC sensors are used to detect room or hot water temperature, enabling energy-saving control and comfort adjustment.

3. Industrial Process Control

NTCEGT sensors are often used in heat treatment on production lines, furnace temperature monitoring, and temperature feedback in chemical processes. Their high sensitivity and reliability ensure process stability.

4. Other Applications

NTCEGT sensors are also used in marine engines, aircraft engines, and some laboratory test equipment because of their high-temperature gas tolerance and accuracy, meeting the demands of demanding environments.

What is the difference between PTC technology and traditional thermocouples?

1. Working Principle

PTC sensors: Based on a positive temperature coefficient thermistor, their resistance increases as the temperature rises; they are a type of resistive temperature measurement. Thermocouples: Utilize the thermoelectric potential (Seebeck effect) generated by a temperature difference between two dissimilar metals to directly output a voltage signal.

2. Temperature Range and Accuracy

PTCs: Suitable for medium to low temperature ranges between -60°C and 150°C, with relatively high accuracy, especially stable in overheat protection scenarios.

Thermocouples: Offer a wide temperature measurement range (-270°C to 2300°C), but their accuracy is slightly inferior to PTCs in the low-temperature range.

3. Response Speed and Linearity

PTCs: Offer fast response and are nearly linear within a certain range, making them easy to directly map to temperature values.

Thermocouples: Offer extremely fast response, but their output is a nonlinear voltage, requiring cold-junction compensation and linearization.

4. Cost and Application Scenarios

PTCs: Simple in structure and low in cost, they are commonly used in low- to medium-temperature applications such as motor overheat protection and home appliance temperature control.

Thermocouples: Costly in manufacturing, they are suitable for industrial environments with high temperatures, severe corrosion, or those requiring long-distance signal transmission.

English

English Español

Español Français

Français

简体中文

简体中文