SOOK#:SKNOX001A Continenal No:5WK96751C,5WK96751A OE#:4326862 Application: Cummins

NOx Sensor Manufacturers

Our NOx sensors are specifically designed for modern internal combustion engines and hybrid vehicles, enabling real-time monitoring of NOx concentrations in exhaust gases to ensure compliance with stringent global emission standards such as Euro 6. As a self-owned manufacturing facility, we offer end-to-end control from research and development to production and testing, delivering highly reliable and cost-effective solutions to customers.

| Range | NOx: 0~1500ppm, O₂: 12%~21% |

| Accuracy NOx | 0~100ppm: ±10ppm |

| 100~500ppm: ±10% | |

| 500~1500ppm: ±15% | |

| Accuracy O₂ | 0%~5%: ±0.25% |

| 5%~21%: ±5% | |

| Response Time | t₁₀↔90% λlin < 4900ms |

| t₁₀↔90% NOx < 5300ms | |

| Power Supply | 12V, 24V |

| Light Off Time | 120s (Devpoint to status byte OK) |

| Design Life Time | 6000h or 350,000km |

| Sensor Cable Length | 415mm, 615mm, 915mm |

| Exhaust Temperature | 800°C |

| Wire Temperature | 200°C |

| Cross Sensitivity | NO₂, NH₃, Pressure |

-

-

5801754015 NOx Sensor

5801754015 NOx SensorSOOK#:SKNOX011 OE#:5801754015 Application: IVECO

-

1782596 NOx Sensor

1782596 NOx SensorSOOK#:SKNOX012 Continenal No:5WK96612D OE#:1782596 Application: SCANIA ...

-

89463-E0013 NOx Sensor

89463-E0013 NOx SensorSOOK#:SKNOX014 Continenal No:5WK96667C OE#:89463-E0013 Application: HINO

-

22219283 NOx Sensor

22219283 NOx SensorSOOK#:SKNOX015 OE#:22219283 Application: Volvo

-

A0009053503 NOx Sensor

A0009053503 NOx SensorSOOK#:SKNOX031 Continenal No:5W96682C OE#:A0009053503 Application:Mercedes-Benz ...

-

CTL number NOx Sensor

CTL number NOx SensorSOOK#:SKNOX079 Continenal No:5WK96714 OE#:CTL number Application: UniNOx

-

68067521AA NOx Sensor

68067521AA NOx SensorSOOK#:SKNOX080 Continenal No:5WK96684A OE#:68067521AA Application: Ram

-

2011649,1793379,1836060 NOx Sensor

2011649,1793379,1836060 NOx SensorSOOK#:SKNOX081 Continenal No:5WK96628C OE#:2011649,1793379,1836060,1697586 Application:DAF

-

2011650 NOx Sensor

2011650 NOx SensorSOOK#:SKNOX082C Continenal No:5WK96626C OE#:2011650 Application: DAF

-

5801443021,5801273980 NOx Sensor

5801443021,5801273980 NOx SensorSOOK#:SKNOX084 Continenal No:5WK96733A OE#:5801443021,5801273980 Application: IVECO

-

5801777219,41271167 NOx Sensor

5801777219,41271167 NOx SensorSOOK#:SKNOX085 Continenal No:5WK96720A OE#:5801777219,41271167 Application: IVECO ...

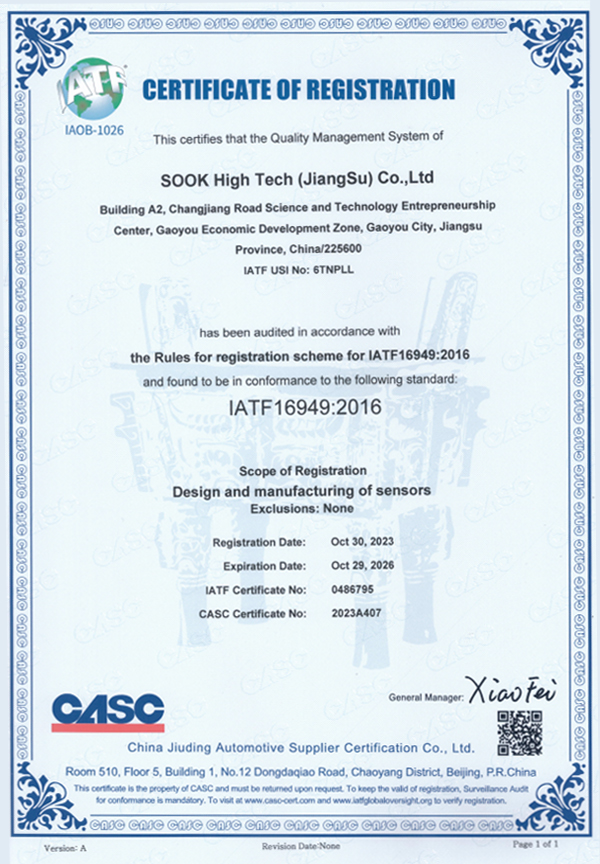

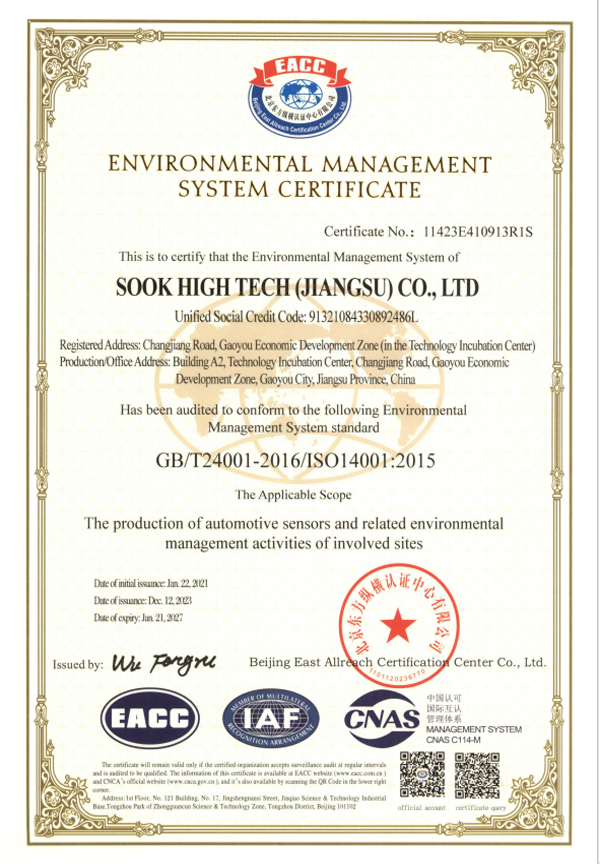

Sook High Tech (Jiangsu) Co., Ltd. was established in 2015, with a registered capital of 30.5 million yuan. Has won High-tech enterprise, National science and technology small and medium-sized enterprise, Software enterprise, Member of China Machinery Industry Standardization Technology Association, Council Members of Sensor and IoT Industry Association, Council Members of China Instrument Industry Association Sensor Branch and Council Members of Jiangsu Import and Export Chamber of Commerce.

As a professional China OEM NOx Sensor Manufacturers and ODM NOx Sensor Factory

, SOOK High Tech focuses on the design, production, sales and integration of various sensors for smart cars and industrial fields, as well as cables and heaters for the industrial field.

Has an annual production capacity of 600,000 sensors of various types. There are more than 2,000 items of exhaust temperature sensors, 450 items of NOx sensors, and 1,300 items of ABS sensor, which are exported to Europe and the United States.

Learn about our industry exhibition information and recent events in our company.

-

What Is a NOx Sensor and Why Is It So Important in Modern Vehicles?

If you work with modern diesel vehicles—or you're responsible for engines, aftertreatment systems, or emission compliance—you’ve probably heard customers ask: "What exactly is a NO...23 -

What is an NTC EGT Sensor?

In the fields of automotive and industrial measurement, the NTC EGT sensor is another widely utilized tool for monitoring exhaust gas temperatures. 1. Definition and Core Principle...16 -

Why are PTC sensors more accurate than ordinary sensors?

In automotive emission monitoring and high-temperature industrial operations, the precision of an Exhaust Gas Temperature (EGT) sensor directly impacts engine efficiency and safety...09 -

What is the specific role of the PTC EGT Sensor in DPF regeneration?

The Specific Role of the PTC EGT Sensor in DPF Regeneration: 1. Real-time Temperature Monitoring The sensor is installed upstream of the DPF and collects exhaust gas temperature in...02

What reset or learning steps are required after replacing a NOx sensor?

1. Clear fault codes and perform a system reset

After replacing a sensor, first use a professional diagnostic tool to read and clear the existing NOx sensor fault codes to ensure the ECU can receive the new sensor's signal.

2. Perform the sensor calibration (learning) procedure

Use the diagnostic tool to access the calibration menu of the emission control system and perform "sensor learning" or "adaptation" according to the manufacturer's instructions. This will allow the ECU to quickly establish a baseline NOx concentration under different operating conditions.

3. Conduct a road test to verify

After completing the reset and learning process, conduct a road test of at least 10 km to monitor exhaust NOx data for stability and confirm that the sensor response time (<1400ms) meets specifications.

4. Recheck the electrical connections

After the road test, recheck the tightness of the sensor connector, wiring harness, and heater circuit to prevent loosening caused by vibration from triggering the fault again.

Why does carbon deposits/soot cause NOx sensor failure? 1. Probe Surface Contamination

After long-term operation, carbon residue and soot in the exhaust gas can deposit on the sensor probe surface, preventing direct gas contact with the sensor element and causing signal attenuation or distortion.

2. Intake Passage Blockage

Carbon deposits can block the sensor's air inlet, reducing airflow and increasing sensor response time, even leading to zero readings.

3. Chemical Corrosion and Electrode Aging

Sulfides and metal particles contained in soot can corrode the electrodes of electrochemical NOx sensors, accelerating component aging and leading to sensor failure.

4. Poor Heat Dissipation

The carbon layer can reduce the sensor's heat dissipation efficiency, causing the operating temperature to rise abnormally, further accelerating the aging and failure of the sensor's internal materials.

English

English Español

Español Français

Français

简体中文

简体中文