SOOK#:SKNH3001 OE#:28608771,2040W2,47520140 Application: New Holland

NH3 Sensor Manufacturers

Our ammonia gas sensors are designed for industrial production environments, offering precise and reliable detection of ammonia (NH₃) concentrations. Engineered to meet the demands of modern manufacturing, these sensors are ideal for applications in chemical plants, refrigeration systems, agricultural facilities, and environmental monitoring.

| Range | 0–200 ppm (~1 ppm detection limit) |

| Accuracy | ±5 ppm:±5% |

| T90 Response Time | 5–10 s |

| NH₃ Cross-Sensitivity | Significantly reduced compared to commercial NOx sensors |

-

-

28608772,3030W1,47520142 Ammonia Sensor

28608772,3030W1,47520142 Ammonia SensorSOOK#:SKNH3002 OE#:28608772,3030W1,47520142 Application: New Holland

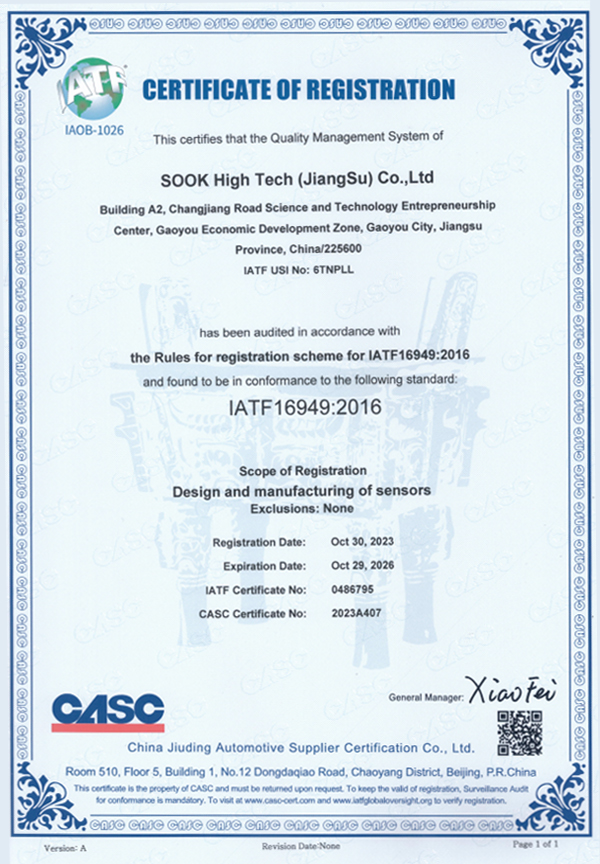

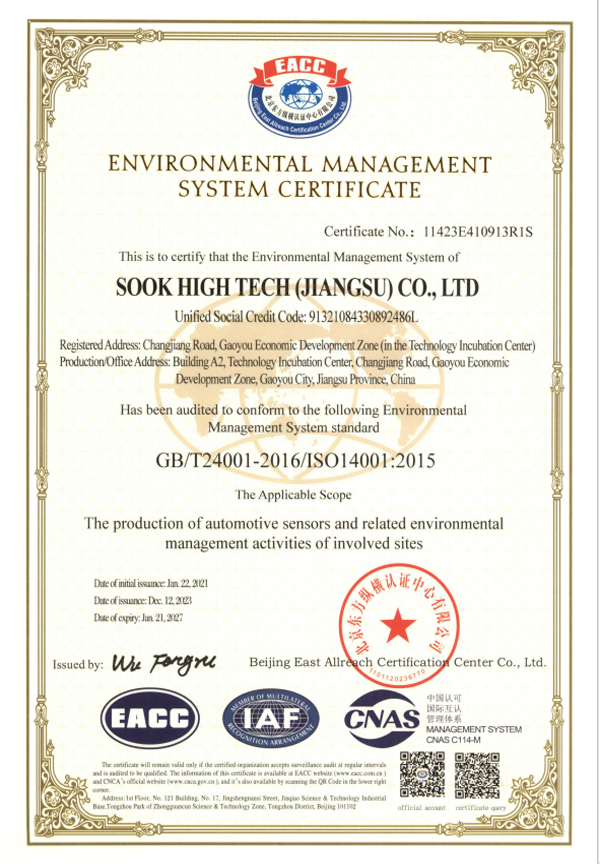

Sook High Tech (Jiangsu) Co., Ltd. was established in 2015, with a registered capital of 30.5 million yuan. Has won High-tech enterprise, National science and technology small and medium-sized enterprise, Software enterprise, Member of China Machinery Industry Standardization Technology Association, Council Members of Sensor and IoT Industry Association, Council Members of China Instrument Industry Association Sensor Branch and Council Members of Jiangsu Import and Export Chamber of Commerce.

As a professional China OEM NH3 Sensor Manufacturers and ODM Automotive Ammonia Sensor Factory

, SOOK High Tech focuses on the design, production, sales and integration of various sensors for smart cars and industrial fields, as well as cables and heaters for the industrial field.

Has an annual production capacity of 600,000 sensors of various types. There are more than 2,000 items of exhaust temperature sensors, 450 items of NOx sensors, and 1,300 items of ABS sensor, which are exported to Europe and the United States.

Learn about our industry exhibition information and recent events in our company.

-

What Is a NOx Sensor and Why Is It So Important in Modern Vehicles?

If you work with modern diesel vehicles—or you're responsible for engines, aftertreatment systems, or emission compliance—you’ve probably heard customers ask: "What exactly is a NO...23 -

What is an NTC EGT Sensor?

In the fields of automotive and industrial measurement, the NTC EGT sensor is another widely utilized tool for monitoring exhaust gas temperatures. 1. Definition and Core Principle...16 -

Why are PTC sensors more accurate than ordinary sensors?

In automotive emission monitoring and high-temperature industrial operations, the precision of an Exhaust Gas Temperature (EGT) sensor directly impacts engine efficiency and safety...09 -

What is the specific role of the PTC EGT Sensor in DPF regeneration?

The Specific Role of the PTC EGT Sensor in DPF Regeneration: 1. Real-time Temperature Monitoring The sensor is installed upstream of the DPF and collects exhaust gas temperature in...02

What are the common types of ammonia sensors on the market?

1. Electrochemical Ammonia Sensor (NH₃ Sensor)

Detects ammonia concentration through an electrochemical reaction, offering fast response and high sensitivity, making it suitable for precise monitoring in chemical plants and laboratories.

Sook High Tech (Jiangsu) Co., Ltd.'s electrochemical sensors use high-purity electrode materials to ensure stable output over a wide temperature range.

2. Semiconductor NH₃ Sensor

This sensor uses changes in surface resistance of a metal oxide semiconductor to sense ammonia. Its structure is simple and cost-effective, making it commonly used in agricultural greenhouses and cold chain facilities.

The company's developed semiconductor sensor features a dustproof and waterproof housing, meeting the demands of harsh industrial environments.

3. Optical (Infrared) Ammonia Sensor

This sensor achieves non-contact detection by absorbing infrared light at specific wavelengths, offering strong anti-interference capabilities and suitable for large-scale emission monitoring systems.

Sook High Tech's optical sensor, equipped with a high-precision wavelength calibration module, enables low-concentration detection in the ppm level. 4. Capacitive Ammonia Sensor

This sensor uses the change in the dielectric constant of the adsorbed layer to measure ammonia concentration, offering a fast response time and suitable for rapid leak detection.

Our company's packaging process for capacitive sensors has achieved high reliability, with an annual production capacity of 600,000 units, enabling rapid delivery of high-volume projects.

How to choose an ammonia sensor installation location?

1. Close to potential leak sources

Installing the sensor upstream of a pipe joint, valve, or tank will detect ammonia leaks immediately.

Sook High Tech's sensors support a variety of wiring methods, allowing for flexible placement in confined spaces.

2. Well-ventilated areas

When selecting a location, avoid dead corners and ensure air circulation, allowing the sensor to obtain a representative gas sample.

Our products feature a self-cleaning function, maintaining measurement accuracy even in low-ventilation environments.

3. Preventing cross-interference

Avoid proximity to strong oxidizers, strong reducing agents, or high-temperature equipment, as these can affect the readings of electrochemical or semiconductor sensors.

Sook High Tech's sensor housings are made of corrosion-resistant materials, ensuring long-term operation in high-concentration chemical media. 4. Ease of Maintenance and Calibration

The installation height should be consistent with operator maintenance habits, typically between 1.2 and 1.8 meters, to facilitate regular replacement or calibration.

The company provides standardized calibration kits and a remote diagnostic platform to reduce maintenance costs.

English

English Español

Español Français

Français

简体中文

简体中文